As a widely used pipe material, ductile iron pipe plays a key role in many fields. However, ultrasonic sound velocity measurement provides an industry-recognized and reliable method to verify the material integrity of parts.

1. Ductile iron pipe and its application

DINSEN ductile iron pipe is a pipe made of ductile iron by centrifugal casting process. It has the advantages of high strength, high toughness, corrosion resistance, high pressure resistance, etc., and is widely used in urban water supply, drainage, gas transmission and other fields.

In urban water supply systems, ductile iron pipes can withstand high water pressure to ensure the safe transportation of water resources. Its good corrosion resistance also makes it less susceptible to erosion by impurities in the water during long-term use, extending the service life of the pipeline. In the drainage system, the high strength and toughness of ductile iron pipes can withstand the scouring of sewage and the action of external forces to ensure the stable operation of the drainage system. In addition, ductile iron pipes also play an important role in fields such as gas transmission. Their good sealing can effectively prevent gas leakage and protect people’s lives and property.

2. Methods and reasons for detecting the spheroidization rate of ductile iron pipes

Detection methods

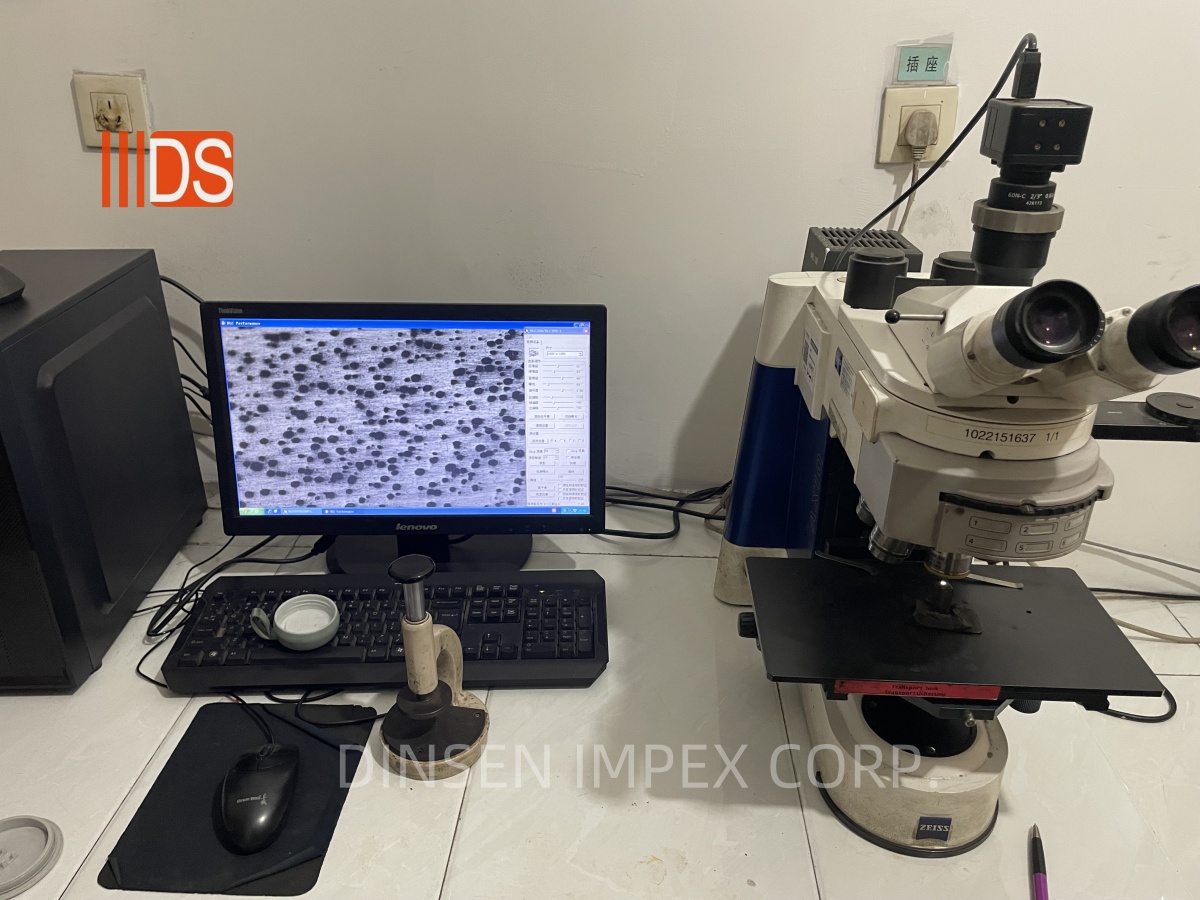

Metallographic analysis method: This is a commonly used method for detecting the spheroidization rate. By preparing metallographic samples of ductile iron pipes, the morphology and distribution of graphite are observed under a microscope to determine the spheroidization rate. The specific steps include sampling, inlaying, grinding, polishing, corrosion and observation. The metallographic analysis method can intuitively observe the spheroidization degree of graphite, but the operation is relatively complicated and requires professional equipment and technicians.

Ultrasonic detection method: The spheroidization rate is detected by using the propagation characteristics of ultrasonic waves in ductile iron pipes. The propagation speed and attenuation of ultrasonic waves in ductile iron with different spheroidization degrees are different. By measuring the parameters of ultrasonic waves, the spheroidization rate can be inferred. This method has the advantages of being fast, non-destructive and accurate, but it requires professional ultrasonic detection equipment and software.

Thermal analysis method: The spheroidization rate is determined by measuring the thermal changes of ductile iron pipes during cooling. Ductile iron with good spheroidization will have specific thermal change curves during cooling. By analyzing these curves, the spheroidization rate can be determined. Thermal analysis has the advantages of simple operation and fast speed, but its accuracy is relatively low.

Reason for testing

Ensure product quality: Spheroidization rate is one of the important indicators of ductile iron pipe quality. The higher the spheroidization rate, the better the strength, toughness and corrosion resistance of the pipe. By testing the spheroidization rate, it can be ensured that the quality of ductile iron pipes meets the standard requirements and provide users with reliable products.

Optimize production process: The test results of spheroidization rate can be fed back to manufacturers to help them optimize the production process. For example, if the spheroidization rate is low, the amount of spheroidizer added, casting temperature and other parameters can be adjusted to increase the spheroidization rate, thereby improving product quality.

Meet customer needs: In some special fields, such as high-pressure gas transmission, the spheroidization rate of ductile iron pipes is very high. By testing the spheroidization rate, it is possible to meet the specific needs of customers and improve the market competitiveness of products.

3. DINSEN laboratory provides ductile iron pipe spheroidization rate testing for Russian customers

Last week, DINSEN laboratory provided ductile iron pipe spheroidization rate testing services for Russian customers. After receiving the client’s commission, we quickly organized a professional technical team and developed a detailed testing plan.

First, we used a combination of metallographic analysis and ultrasonic testing to conduct a comprehensive test of the ductile iron pipe. The metallographic analysis results showed that the graphite in the ductile iron pipe had a good morphology and a high spheroidization rate. The ultrasonic test results were also consistent with the metallographic analysis results, further verifying the accuracy of the test results.

Secondly, we provided the client with a detailed test report, including the test method, test results, analysis conclusions, etc. The client was very satisfied with our testing service and said that he would continue to cooperate with us.

Through this testing service, we not only provided Russian customers with high-quality test results, but also accumulated rich experience in spheroidization rate testing of ductile iron pipes. We will continue to work hard to provide customers with more professional and efficient testing services and contribute to the development of the ductile iron pipe industry.

In short, the spheroidization rate test of ductile iron pipes is an important means to ensure product quality, optimize production processes, and meet customer needs. DINSEN Laboratory will continue to provide customers with professional testing services and contribute to the development of the ductile iron pipe industry.

Post time: Dec-17-2024