-

Introduction to DI Pipe Jointing Systems: Procedure

Rubber Gasket The absence of sunlight and oxygen, presence of moisture/water, relatively lower and uniform surrounding temperature in buried conditions help in preservation of rubber gaskets. Thus this type of joint is expected to last for more than 100 years. – Good qualily Synthetic ru...Read more -

Introduction to DI Pipe Jointing Systems

Electrosteel D]. Pipes and Fittings are available with following types of jointing systems: – Socket & Spigot Flexible Push-on Joints – Restrained Joints Push-on Type – Mechanical Flexible Joints (only fittings) – Flanged Joint Socket & Spigot Flexible Push...Read more -

Reducing Scrap Rates and Enhancing Parts Quality in Casting Foundries

Casting foundries play a crucial role in the manufacturing industry, producing components for a wide range of applications, from automotive to aerospace. However, one of the persistent challenges they face is reducing scrap rates while maintaining or improving parts quality. High scrap rates ...Read more -

How to Cut Cast Iron Pipe: A Step-by-Step Guide

Dinsen Impex Corp is a professional supplier of cast iron drainage pipe systems in China. Our pipes are supplied in standard lengths of 3 meters but can be cut to the required size. Proper cutting ensures that the edges are clean, right-angled, and free from burrs. This guide will teach you two m...Read more -

Common Casting Defects: Causes and Prevention Methods – Part II

Six Common Casting Defects: Causes and Prevention Methods (Part 2) In this continuation, we cover three additional common casting defects and their causes, along with prevention methods to help reduce defects in your foundry operations. 4. Crack (Hot Crack, Cold Crack) Features: Cracks in casting...Read more -

Common Casting Defects: Causes and Prevention Methods

In the casting production process, defects are a common occurrence that can result in significant losses for manufacturers. Understanding the causes and applying effective prevention methods is critical for quality assurance. Below are the most common casting defects along with their causes and r...Read more -

Our New Product: Rainwater Pipes And Fittings

Dinsen Impex Corp is a leading provider of EN877 cast iron pipes, offering a comprehensive range of rainwater pipes and fittings. Our products feature a standard gray metal primer with a rust inhibitor, ensuring long-lasting durability and resistance to corrosion. With our cast iron rainwater pro...Read more -

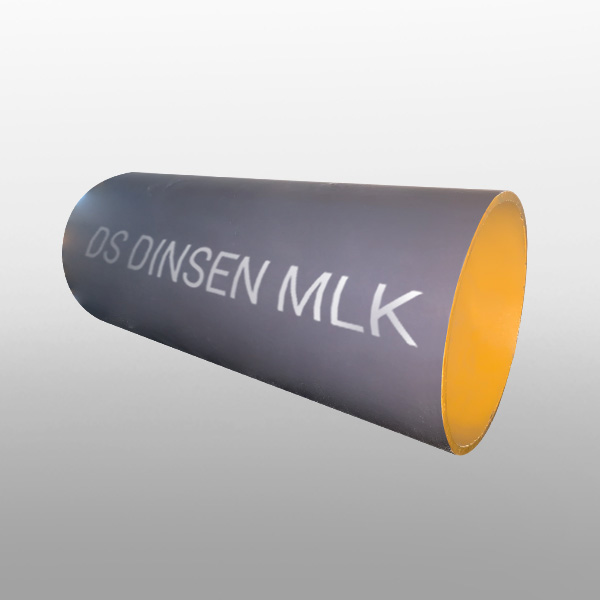

Introduction to Different Types of Cast Iron SML Pipe Fittings

Cast Iron SML Bend (88°/68°/45°/30°/15°): used to change the direction of pipe runs, typically at 90 degrees. Cast Iron SML Bend With Door (88°/68°/45°): used to change the direction of pipe runs while providing an access point for cleaning or inspection. Cast Iron SML Single Branch (88°/...Read more -

Issues with Ordinary (Non-SML) Cast Iron Pipes in Building Drainage: The Need for Repair

While cast iron pipes are expected to have a lifespan of up to 100 years, those in millions of homes in regions like Southern Florida have failed in as little as 25 years. The reasons for this accelerated degradation are weather conditions and environmental factors. Repairing these pipes can be v...Read more -

DINSEN® Cast Iron TML Pipe and Fittings

Casting quality TML pipes and fittings made from cast iron with flake graphite in accordance with DIN 1561. Benefits Robustness and high corrosion protection thanks to the high-quality coating with zinc and epoxy resin distinguish this TML product range from RSP®. Couplings Single or double-screw...Read more -

DINSEN® Cast Iron BML Pipe and Fittings

BML (MLB) Pipes for Bridge Drainage Systems BML stands for “Brückenentwässerung muffenlos” – German for “Bridge drainage socketless”. BML pipes and fittings casting quality: cast iron with flake graphite in accordance with DIN 1561. DINSEN® BML bridge drainage pipes are designed to me...Read more -

DINSEN® Cast Iron KML Pipe and Fittings

KML Pipes for Grease-Containing or Corrosive Wastewaters KML stands for Küchenentwässerung muffenlos (German for “kitchen sewage socketless”) or Korrosionsbeständig muffenlos (“corrosion-resistant socketless”). KML pipes and fittings casting quality: Cast iron with flake graphite in accordance wi...Read more